Global Production Lines Secure Global Standard Quality

With full-digital manufacturing management and fully automated intelligent assembly processes, BWI Group’s One-Box system production line is capable of highly reliable and flexible manufacturing

BWI Group has recently begun pilot production in China of the intelligent integrated brake-by-wire system iDBC1 (One-Box).

BEIJING, 中国, February 8, 2024 /EINPresswire.com/ -- BWI Group has recently begun pilot production in China of the intelligent integrated brake-by-wire system iDBC1 (One-Box), which is subsequently due to be mass-produced in Europe. The first batch of products will be exported to Europe to be equipped on mainstream models from well-known automobile brands and will also be mass-produced for models from a major automotive OEM in the United States.As a tier-one supplier of high-end braking and suspension systems serving numerous automobile companies around the world, BWI Group has independently designed and developed the fully automated production line for the One-Box braking system. Building upon production quality systems experience gained when the company was part of Delphi Corporation, BWI Group has implemented strategies and solutions for product testing and error-proofing to ensure all products reach a high level of quality.

BWI Group’s first intelligent integrated brake-by-wire system iDBC1 (One-Box) fully automated production line will be completed this February and begin official operation in the second quarter.

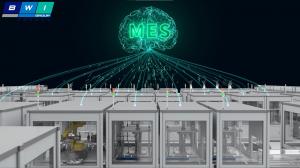

The production line achieves the accurate and automatic transfer of workpieces through high-precision conveyor lines. Utilizing full-digital manufacturing management and highly automated intelligent assembly processes, it is capable of highly reliable and flexible manufacturing. At the end of the process, each product undergoes rigorous testing and comparison error-proofing to ensure superior product quality.

With more than 100 years of technological development accumulated from Delco and Delphi, BWI Group has mastered the world-leading core technology of One-Box. The company has more than 25 years of experience in electronically controlled brake system development and mass production from ABS to ESC. BWI Group’s One-Box system production effort will always adhere to international standards in terms of production process control, parameter control, traceability, and complying with global standards.

The production line applies a fully digitalized Manufacturing Execution System (MES) to ensure that each process meets the required standards and that the products are traceable.

Each session is monitored by quality control throughout the whole process, and the data is uploaded to MES in real-time as it is generated. By collecting very specific production data, MES manages quality control, data analysis, energy management, intelligent warehousing, and other functions. The manufacturing process is recorded in conjunction with the process parameters, which ease the analysis and ensure the continuous stability of the manufacturing process. Meanwhile, the system also scans product information to compare and prevent mistakes from happening, keeping the whole process under control and ensuring traceability.

The process solution of flexible production line assembly combines the traditional advantages of BWI Group with the leading technology in the industry. The process development is oriented to facilitate mass production and can quickly adapt to changes in market demand, product design updates, and changes in the manufacturing process. This effectively enables mass customization while efficiently controlling the production process.

Key manufacturing stations incorporate the latest world-leading control programs, utilizing production equipment from well-known and highly respected Suppliers. The whole process is under strict quality control, ensuring cleanliness and durability. The automated product performance test station, independently developed by BWI Group, uses a well-respected vision inspection system to ensure the reliability and quality of assembly inspection and excellent product quality.

BWI Group has laid out a global plan, fully utilizing its advantages in mass production of One-Box systems to accelerate the realization of mass production in Europe. The One-Box system production line will radiate to European and North American markets, providing high-quality products for customers of internationally renowned automobile groups.

BWI Group

BWI Group

media@bwigroup.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.